As all in the construction industry know, having the right tools for the job is essential. And when it comes to moving glass panes, there is no better tool than the Glass Boy!

If you are familiar with vacuum lifting tools, you have probably come across the Glass Boy (or the cladding counterpart Clad Boy). The “Boy” brand is at the forefront of panel suction machinery, making it a top seller worldwide.

This guide will break down what makes the Glass Boy so great. We’ll look at the full range, their amazing features and their uses. Here’s everything you need to know about the Glass Boy.

What is the Glass Boy?

So, the burning question is the reason we’re all here. What is the Glass Boy?

In simple terms, the Glass Boy is a vacuum lifting tool specifically designed for glass panels. But really, it’s so much more than that.

The Glass Boy vacuum lifter is an industry-leading piece of equipment designed for the precise and secure manoeuvring of glass. Renowned for its excellent vacuum strength, it ensures that glass panels are handled with the utmost care, minimising the risk of dropping and damage.

Built for strength, durability, and reliability, the Glass Boy range is a trusted solution for various lifting needs. Equipped with innovative suction cup technology, these lifters effortlessly handle heavy-duty glass precisely, making them ideal for use between floors or rooftops.

The inclusion of an electric hoist and a hydraulic lifting arm guarantees efficient and consistent performance, while a variety of models offer safe working loads tailored to different requirements, ensuring there is a Glass Boy vacuum lifter suitable for every job.

Who is the Glass Boy For?

The Glass Boy is designed for professionals in the construction and glazing industries who require a reliable and efficient solution for handling glass. This includes glass installers, construction workers, and maintenance teams working on projects that involve the transportation and installation of large glass panels.

Whether operating on multi-story buildings, rooftops, or ground-level sites, these vacuum lifters provide the necessary strength, precision, and safety needed for demanding tasks.

Ideal for both commercial and residential projects, the Glass Boy meets the needs of those who prioritise quality and dependability in their glass lifting equipment.

Glass Boy Vacuum Lifter’s Features

The Glass Boy vacuum lifter is packed with features designed to meet the diverse needs of glass installation professionals. From its versatile model range to its advanced safety mechanisms, the Glass Boy stands out as a reliable and efficient tool for handling glass. Here are some of the key features that make the Glass Boy an industry leader in glass lifting equipment.

Variety of Models

The Glass Boy vacuum lifter range offers a diverse selection of models, ensuring there is a suitable option for every glass installation project, regardless of size or complexity. This versatility makes Glass Boy the go-to choice for a wide range of professional applications.

Amazing Capacity

Each model in the Glass Boy lineup is designed to handle impressive lifting capacities, maintaining optimal performance within its specified weight range. This ensures that you can confidently lift heavy glass panels without compromising safety or efficiency.

Advanced Safety Features

Safety is a paramount concern with the Glass Boy range. Featuring dual and quad circuit systems, these lifters provide enhanced safety measures to prevent accidents. Additionally, the inclusion of low-battery warning systems ensures that the equipment remains reliable and operational at all times.

Multiple Configurations

Glass Boy lifters are highly adaptable, offering multiple configuration options to accommodate glass panels of various shapes and sizes. This flexibility makes them ideal for a wide array of glass handling tasks, providing a customised solution for each project.

Built-in Charger

Equipped with built-in chargers, the battery-operated Glass Boy lifters offer the convenience of easy recharging, ensuring that the equipment is always ready for use when needed.

Regulatory Compliant

The entire Glass Boy range complies with relevant UK, European, and worldwide regulations and legislation. This compliance guarantees that the equipment meets the highest standards of safety and performance, providing peace of mind for users operating in any region.

Meet The Full Glass Boy Range

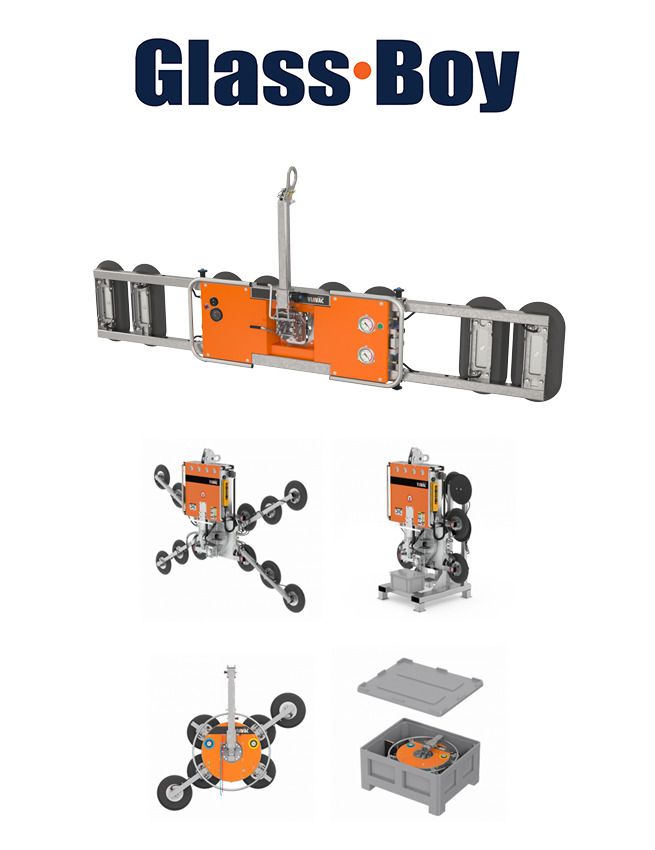

Did you know the Glass Boy isn’t just one product? VIAVAC has designed a range of products, each tailored to unique uses. There is a Glass Boy to help you get the job done quickly and safely, whatever your glass-lifting task.

Glass Boy GB-L

The Glass Boy GB-L is the smallest in the range and the perfect place to start. Just because it’s small doesn’t mean it’s not packed with potential. This compact contraption may come in a small storage cradle, but it can still support a fair amount of weight. The GB-L can lift up to 500 kg and support glass panels measuring 3m x 4m. It’s a powerful tool that will save you time on a variety of projects. With the savings in labour costs alone, this thing will pay for itself in no time.

Glass Boy GB-X

The next step in the range is the GB-X. This tool can support a weight of 400 kg—800 kg, which is impressive compared to the GB-L. The dimensions of the glass panels also increase, as the Glass Boy GB-X can support 4m x 4m glass elements. Another stand-out feature of this model is its versatility. This tool provides six different configurations. With the GB-X, you can move and install glass elements of a wide array of shapes and sizes.

Glass Boy GB-H

The largest offering in the Glass Boy range, the GB-H, provides a staggering 1800 kg lift capacity. The GB-H has powered tilting and rotation and features remote control vacuum operation. Despite boasting these impressive lifting capabilities, the GB-H is still easy to transport. It comes in a standard pallet footprint cradle.

Operating Glass Boy Products

VIAVAC have done an amazing job of building safety into their products. The Glass Boy’s dual circuit is just one example of how safety was made a top priority with these products. The very product itself is designed around safety, preventing injury from manual heavy lifting. But full safety includes proper operation training and support. To get the most from any Glass Boy product, ensure your team undergo the necessary vacuum lifter training.

Stay Safe With The Right Tools

If you work with glass panels, the GB range is a must-have. It is key to safety and will make your installations run more smoothly. And who can say no to a safer, more efficient work site?

Ready to elevate your glass installation projects with the best in the industry? Explore the full range of Glass Boy vacuum lifters available at 4 Cladding and discover the perfect model to meet your needs. Don’t miss out on our comprehensive training and maintenance services, designed to ensure you get the most out of your equipment. Call us today to learn how the Glass Boy can transform your workflow with unmatched strength, precision, and safety.

Glass Boy Frequently Asked Questions

How Much Can A Glass Boy Lift?

The largest Glass Boy in the range, the Glass Boy GB-H, can lift an impressive 1,800 kg.

Who Makes Glass Boy Products?

The Glass Boy glass lifter range is brought to you by vacuum lifting experts VIAVAC. Recognised worldwide for their incredible vacuum lifting products, VIAVAC are behind some of the most recognisable and most loved tools in the construction industry including the Glass Boy, Clad Boy, Cool Boy, and Rota Boy ranges.

They are one of the most respected and trustworthy brands in the industry with a well-earned reputation for creating fantastic products that prioritise safety. Their vacuum lifters are designed to reduce the risk of injury by manually lifting heavy panels. Instead, their lifters make light work panel installations, keeping you safe and saving you time.

What Is The Difference Between A Single And Double Circuit?

CE directives state that all vacuum lifters must be used alongside secondary safety devices. Suppose you are operating a single–circuit vacuum lifter. In that case, you must also take extra safety measures, such as supporting the load with safety straps. Operating lifting tools with dual circuits removes the need for additional safety measures and supports. The additional circuit is the safety measure, a backup just in case. Both the GB-L and GB-X are dual circuits. And the GB-H is a quad circuit!

Related Blogs

How to Safely Transport Glass Panes

Everything You Need to Know About Vacuum Lifters

Choosing the Right Vacuum Lifter for Your Application